Effective Approaches for Accomplishing Ideal Foam Control in Chemical Production

Effective foam control is a critical facet of chemical production that can considerably influence production effectiveness and product high quality. By understanding the systems of foam development and selecting suitable anti-foaming representatives, producers can take aggressive steps to alleviate too much foam. In addition, the application of process optimization methods and progressed tracking systems plays a vital function in preserving optimal operating conditions. However, the nuances of these approaches can vary extensively throughout different applications, increasing crucial inquiries regarding ideal practices and real-world applications that merit additional exploration.

Comprehending Foam Formation

Surfactants, or surface-active agents, reduce the surface stress of the liquid, assisting in bubble security and promoting foam generation. Additionally, agitation or mixing procedures can boost bubble development, usually worsening foam problems. The attributes of the fluid tool, including thickness and thickness, further influence foam habits; for instance, even more viscous liquids often tend to catch air much more efficiently, causing increased foam stability.

Recognizing these basic elements of foam formation is important for efficient foam control in chemical manufacturing. By recognizing the conditions that promote foam growth, manufacturers can execute targeted approaches to mitigate its negative effects, thereby enhancing production processes and making certain consistent product quality. This fundamental understanding is important before exploring details approaches for regulating foam in commercial settings.

Choice of Anti-Foaming Agents

When selecting anti-foaming agents, it is important to take into consideration the details features of the chemical procedure and the sort of foam being generated (Foam Control). Various factors affect the effectiveness of an anti-foaming representative, including its chemical make-up, temperature level stability, and compatibility with various other procedure products

Silicone-based anti-foams are commonly made use of due to their high efficiency and broad temperature variety. They work by lowering surface area tension, allowing the foam bubbles to coalesce and break more quickly. They may not be appropriate for all applications, specifically those including delicate formulas where silicone contamination is a worry.

On the other hand, non-silicone representatives, such as mineral oils or natural substances, can be advantageous in particular circumstances, particularly when silicone residues are unwanted. These agents tend to be much less reliable at higher temperatures however can give reliable foam control in other problems.

In addition, comprehending the foam's origin-- whether it emerges from oygenation, anxiety, or chain reactions-- overviews the option procedure. Testing under real operating conditions is crucial to guarantee that the chosen anti-foaming agent satisfies the distinct needs of the chemical production procedure properly.

Refine Optimization Methods

Effective foam control is a vital facet of optimizing chemical production procedures. By fine-tuning these parameters, drivers can decrease disturbance, thus reducing foam formation during mixing.

In addition, managing temperature and stress within the system can dramatically impact foam generation. Reducing the temperature may minimize the volatility of certain elements, bring about lowered foam. Likewise, keeping optimal pressure degrees helps in mitigating extreme gas launch, which adds to foam stability (Foam Control).

One more effective strategy is the calculated enhancement of anti-foaming agents at crucial phases of the process. Cautious timing and dose can ensure that these representatives effectively subdue foam without interrupting other process specifications.

Furthermore, integrating an organized assessment of raw material properties can assist identify inherently frothing substances, allowing for preemptive steps. Last but not least, performing regular audits and procedure testimonials can disclose inadequacies and areas for improvement, allowing constant optimization of foam control strategies.

Tracking and Control Solution

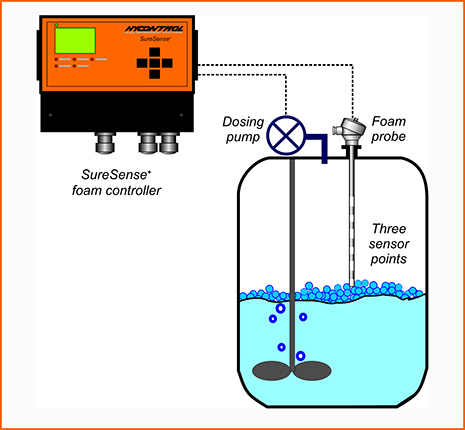

Tracking and control systems play a crucial duty in preserving optimum foam monitoring throughout the chemical production procedure. These systems are crucial for real-time monitoring and adjustment of foam levels, ensuring that production performance is optimized while lessening interruptions triggered by excessive foam formation.

Advanced sensing units and instrumentation are used to spot foam density and elevation, giving Read Full Article important data that informs control algorithms. This data-driven technique enables the prompt application of antifoaming representatives, ensuring that foam degrees remain within appropriate limitations. By incorporating tracking systems with process control software application, suppliers can execute computerized responses to foam variations, reducing the requirement for hands-on intervention and enhancing operational consistency.

Furthermore, the assimilation of equipment discovering and anticipating analytics into checking systems can promote aggressive foam monitoring. By evaluating historical foam information and functional parameters, these systems can forecast foam generation patterns and recommend preemptive steps. Routine calibration and upkeep of monitoring devices are vital to ensure accuracy and integrity in foam discovery.

Inevitably, reliable surveillance and control systems are essential for enhancing foam control, advertising security, and boosting general efficiency in have a peek at this website chemical production atmospheres.

Situation Research Studies and Finest Practices

Real-world applications of surveillance and control systems highlight the importance of foam administration in chemical production. A significant instance research includes a large pharmaceutical producer that implemented an automated foam detection system.

An additional exemplary situation originates from a petrochemical business that embraced a combination of antifoam agents and process optimization techniques. By assessing foam generation patterns, the organization tailored its antifoam dosage, resulting in a 25% reduction in chemical use and significant cost financial savings. This targeted approach not just lessened foam disturbance yet also boosted the overall stability of the production process.

Verdict

Finally, attaining optimal foam control in chemical production necessitates a detailed approach encompassing the selection of ideal anti-foaming representatives, implementation of procedure optimization methods, and the integration of sophisticated surveillance systems. Regular audits and training find out here now additionally boost the performance of these techniques, promoting a culture of continuous enhancement. By addressing foam formation proactively, manufacturers can substantially boost manufacturing effectiveness and item quality, ultimately adding to more lasting and cost-effective operations.

By understanding the devices of foam formation and picking suitable anti-foaming agents, makers can take positive measures to reduce excessive foam. The features of the liquid tool, including viscosity and density, more impact foam habits; for example, even more thick liquids have a tendency to trap air more efficiently, leading to raised foam security.

Recognizing these fundamental aspects of foam formation is vital for effective foam control in chemical manufacturing. By assessing historical foam information and operational specifications, these systems can anticipate foam generation patterns and advise preemptive actions. Foam Control. Normal audits of foam control gauges make sure that procedures stay maximized, while fostering a society of aggressive foam monitoring can lead to lasting renovations across the production range